Delivery That Goes Beyond Expectations

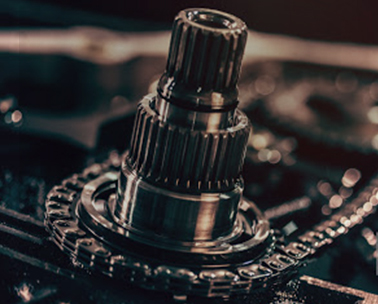

A journey begun in 2003, with a vision to provide ‘Value Added Solutions’, a ‘One Stop Solution’ in the Engineering Sector. The focus of our business was to go beyond clients’ needs, deliver more than the Client’s expectation. Today Cast Craft is a name trusted across various industry sectors, with capabilities established in providing multiple engineering solutions, services, and products. Our wide array of expertise ranging from Oil & Gas, Aerospace, Wind Energy, Power, Railways, to General Engineering. The services range from precision machining to assemblies and sub-assemblies.

Read More- Business Type

- Manufacturer & Exports

- Year of Establishment

- 2003

- Legal Status of Firm

- Private Limited

- Major Markets

- Worldwide/ Global

Our Products

We are the OEM manufacturer and supplier for a leading European Valve manufacturer, with expertise in manufacturing Single Acting Spring Return Pneumatic Valve Actuators with Hydraulic dampener, Hydraulic Actuators, and Double Acting Pneumatic Actuators with Hydraulic dampener

Capabilities

Cast Craft is catering and delivering to a wide range of customer projects as per specific requirements. With a state-of-the-art hydraulic and pneumatic test facility, and fully integrated assembly shop, our high-precision assembly process ensures perfection beyond imagination. The Hydaulic flushing Test facility is designed and is carried out as per NAS/ISO Standards.

Cast Craft harnesses the expertise achieved in the segments of sourcing products, economic assembly and manufacturing, and uses it to create similar models for the purpose of White Labelled Manufacturing and Captive Manufacturing.

Quality Assurance

Inspection & Testing Facilities

Quality assurance and reliability pave the path to our success. To ensure its continuity, we have partnered with the state-of-the-art strategic testing facilities for:

- NDT (DPT,UT,MPT)

- Radiography & Fluorescent test

- Lab for Material test – Chemical, Mechanical, Hardness & Impact

Testimonials

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Cum obcaecati magnam sequi neque tempora, ipsum voluptas vitae dicta, cumque officia.

Gangadharan - MothalaliLorem ipsum dolor sit amet, consectetur adipisicing elit. Cum obcaecati magnam sequi neque tempora, ipsum voluptas vitae dicta, cumque officia.

Maranan - Juniversal and JuniversalLorem ipsum dolor sit amet, consectetur adipisicing elit. Cum obcaecati magnam sequi neque tempora, ipsum voluptas vitae dicta, cumque officia.

Uthaman - Manager